Enhancing Visibility and Control: Dynamics 365 Supply Chain Management Capabilities

How the Dynamics 365 Supply Chain Management solution ensures a more optimized supply chain.

#FocusOnBestPractices

Disruptions in the supply chain result in uncertainties for your business as well as customers. At times, such disruptions are localized and small, affecting only a small number of companies or industries, but there are times when supply chain disruptions are felt worldwide.

The pandemic caused a considerable upheaval in the supply chain system of many businesses in North America.

According to a study by the Institute of Supply Chain Management, nearly 75 percent of the 628 companies surveyed had experienced disruptions in their supply chain services due to the pandemic. In the same survey, 57 percent of participants stated that they faced longer lead times for orders having suppliers in China.

So, how can your company alleviate the negative outcomes of supply chain disruptions and overcome them? This blog will throw light on what disruption is, the kinds of supply chain disruptions, and highlight effective ways to manage supply chain disruptions.

Your supply chain is a network of businesses, people, and actions to help move your product from a supplier to the end customer. A disruption is an unexpected crisis or change, local or international, affecting the process negatively. Supply chain optimization is the proactive approach to improving efficiency and resilience within this network.

A standard supply chain may commence with raw materials, then via a supplier, the producer, the distributor, and next the retailer, and finally reach the consumer. Various kinds of products have unique supply chains. For example, a smartphone has a more complicated supply chain compared to a fruit.

Disruption in the supply chain services is part of any business, however, since the pandemic, the interruption has become quite common. It was projected that supply chain disruption will cost American businesses a whopping $228 million in the year 2021.

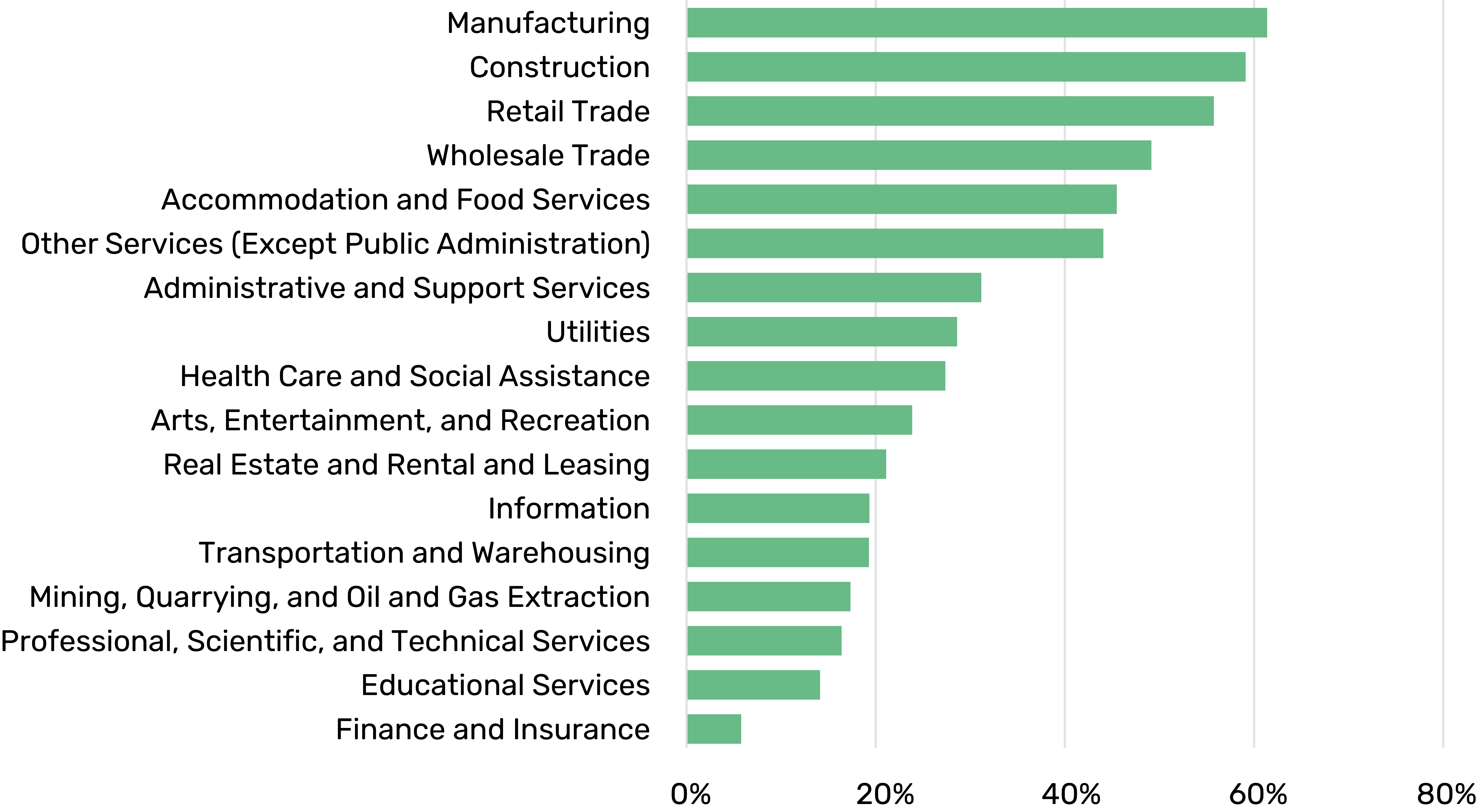

Which sectors received the brunt of disruption? Based on a 2021 survey conducted by the US Census Bureau, the construction, manufacturing, wholesale, food, and retail experienced the maximum impact of supply chain disruption.

Before you learn to manage supply chain disturbances, it’s essential to assess the various kinds of disruptions that occur. Here are some of the major supply chain challenges or scenarios:

Natural calamities: In 2011, the tsunami in Japan resulted in a nuclear catastrophe affecting the Fukushima Daiichi Nuclear Power Plant. The disaster affected several companies as well as the world economy, shutting down those businesses manufacturing 22 percent of the global supply of 300-mm silicon wafers, an essential element used in semiconductors together with 60 percent of essential auto parts.

Delays in transportation: Increased trade and globalization have increasingly made supply chains involve global suppliers. This leads to more business opportunities, however, results in more strain on global as well as domestic transportation networks leading to delays and congestion.

Cyber Attacks: Today, digital technology powers your supply chain, keeping systems up and running. However, it also leaves systems vulnerable to cyberattacks. So, your business should invest in dependable cyber protection to keep your data secure. Any vulnerability will fail your internal systems, and breaches will make customers look somewhere else for products. To safeguard your supply chain and data, consider supply chain optimization services that enhance both security and efficiency.

Pandemic: Nothing has created quite so much havoc on your supply chain as the recent pandemic. The first outbreak led to the shutdown of complete supply chains, and quite a number of them are still pulling through from the impact. Cargo ships were delayed, and there were very few truck drivers available owing to the labor shortage in the US. All of these led to a disruption in the supply chain.

Price variations: Changes in resources, supplier availability, and many other factors can result in price variations for manufacturing as well as transportation. It can lead to delays in shipment or operational overhauls as companies wait for prices to dip or even risk raising prices for consumers.

When your supply chain is disrupted, most of the time it’s out of your control. However, your business can prepare for such challenges in a better way by employing supply chain management strategies to reduce disruption. Here is how:

Automate your processes: Improved automation will help in balancing your stock levels, warehousing expenditures, and consumer demand. Automation related to prediction improves inventory, reduces overhead expenses, and averts the chances of stockouts as well as inventory scarcities. Supply chain optimization strategies can also leverage such advanced automation solutions.

Partner with peers in the industry: Understanding today’s supply chain complexity, the conventional operating approaches using spreadsheets will not help. Constant and nonstop cooperation with peers in the industry, regulators, vendors, financiers, manufacturers, as well as logistics teams is essential to keep your supply chain in action. Software tools having automated permissions, data-rich dashboards, alerts, and updates in real-time will make partnerships simple and practical.

Get complete visibility: Optimize your supply chain visibility by leveraging inventory management solutions to help you prevent disruptions faster. For effective management of supply chain operations, get full visibility, right from raw materials procurement from suppliers to final delivery to your consumers. Achieve this by monitoring and tracking your supply chain using data logging. Data analysis helps to control the entire process effectively.

Spend on appropriate technology: In your latest and secure digital network, you’ll require integrated data from sales, customers, suppliers, and manufacturers via up-to-the-minute inventory management systems to connect you to your manufacturing facilities, suppliers, warehouses, as well as a sales organization.

So, spend on an apt supply chain solution and inventory management software providing elaborate, real-time visibility into your supply chain and inventory management, including stock on order, inventory levels, as well as supplier on-time efficiency or performance. When you know about the stock levels at the vendors’ warehouse as well as raw materials availability from suppliers, it will help you to avert instability in your supply chain services. Remember, investing in technology is comparatively cheaper than lost sales due to the absence of stock.

Do you use customer engagement tools? If yes, you must have heard about ‘Success by Design’, which is a consulting approach. So, if you’re looking for supply chain management as well as optimization, our experts will discuss with you to understand your business and recommend the best-fit solution.

Success by Design consists of three essential principles of Early Breakthrough, Proactive Assistance, and Predictable Achievement. We’ll add knowledge and skills of working on multiple projects and share the best practices to avoid supply chain disruptions and employ an efficient supply chain system successfully.

A resilient and agile supply chain is what you need to overcome disruptions and challenges. However, agility and resilience can’t be developed without careful consideration of its design, execution, as well as operation. This calls for a change in the outlook, the integration of modern tools and technology, and the incorporation of agility and risk KPIs together with the conventional KPIs of quality, cost, as well as service levels. Request a free consultation today.

How the Dynamics 365 Supply Chain Management solution ensures a more optimized supply chain.

During a recession, the impact on the supply chain can be significant. There are some key considerations to understand the effect, overcome the challenges, and make your supply chain recession-proof.

Dynamics 365 Advanced Warehouse Management helps global businesses to boost supply chain resilience with the all-new cloud and edge scale add-ins, allowing them to efficiently distribute their manufacturing and warehousing workloads across geographies.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |