Augmented Reality: How It Works & Its Impact in 2025

In today’s modern world having a cell phone is a must. You carry your device with you everywhere you go so you can check your texts, social media, and take pictures.

#FocusOnBestPractices

Technology is always changing and there are trends which you need to know to shape and transform your business to evolve with the change.

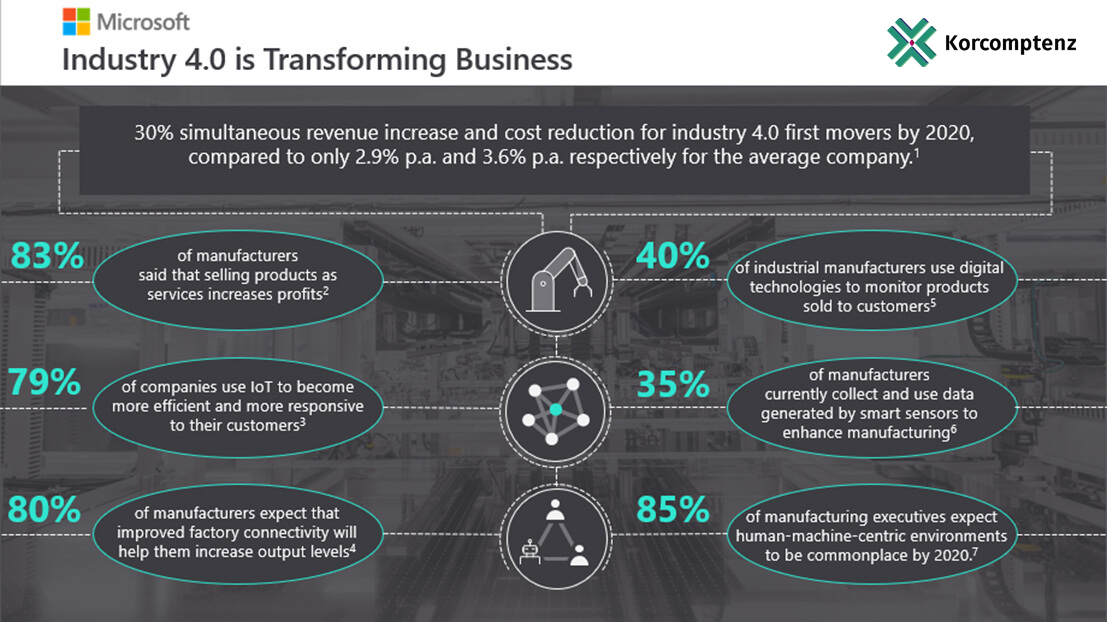

We are currently in the midst of Industry 4.0, where manufacturing has become “smart” through the development of AI, the Cloud, the Internet of Things, and other such systems. The basic principle behind the fourth industrial revolution was that through linking machines and other intelligent devices, manufacturers could create smart networks throughout the value chain (from materials to production) that could control each other.

We’re living in an era of Moore’s Law—the Intel co-founder’s dictum that processing power would double every 18 months. However, it’s not the evolution in microchip technology that’s causing such rapid acceleration in industry, it’s the nature of the software. The emerging combination of big data and intelligent algorithms, often called machine learning and AI, connected by an increasingly ubiquitous mobile internet is on the cusp of changing everything.

The marriage between man and machine will help merge the high-speed accuracy of industrial automation with the cognitive, critical thinking skills of humans. Industry 4.0 is generally viewed as a new era of personalization driven by humans and machines working cooperatively together to solve problems.

While the World Economic Forum predicts that by 2022, Artificial Intelligence will have eliminated 75 million jobs due to automation. Again, 85 million jobs will be lost globally to automation by the year 2025. They also predict that there will be 133 million more jobs created in their place due to the use of this technology. Further, machines will result in the generation of 58 million new jobs as well.

As you go deeper into Industry 4.0, you can create even higher-value jobs than you did before because you’re giving the freedom of design responsibility back to the human. Industry 4.0 technologies are not about replacing humans in the workplace but about getting rid of outdated and “dead-weight” processes and using humans in much more valuable positions.

Another recent study from Meggitt shows that the workspace doesn’t become smaller in terms of a manufacturing cell around the human being; it becomes bigger. The human being is given more responsibility and you end up with a bigger, lighter environment that’s safer than the previous one. The manufacturing operative within the manufacturing cell starts to become more involved in the design process rather than the manufacturing process, which is automated. It allows freedom of design to work with you and enables products that are more bespoke and personal – something that customers are beginning to demand even today.

Increasingly more manufacturers are increasing the human component not only for the customization, but also for increased efficiency on the production line. One example is Toronto’s Paradigm Electronics, which manufactures high-end loudspeakers. The company uses Universal Robots’ UR10 robotic arm to polish the speaker cabs to a high-luster sheen, but it takes considerable time to do so. By adding a human counterpart, however, it increased its production efficiency by 50%.

The idea of collaboration between humans and robots on the assembly line is not a vision of the distant future. In a recent survey by Deloitte, of more than 11,000 business leaders, 61 percent of respondents said they were actively redesigning jobs around artificial intelligence (AI), robotics, and new business models.

It’s not difficult to imagine a few other simple scenarios that are likely to become commonplace under Industry 4.0:

Requesting a consultation with a proven provider is the first step in getting your organization ready for Industry 4.0 technologies. The market is complicated and so is your business. You need an expert to help understand your needs and provide a plan for the future. KORCOMPTENZ can help. Schedule your complimentary consultation today.

In today’s modern world having a cell phone is a must. You carry your device with you everywhere you go so you can check your texts, social media, and take pictures.

Lowering the costs of production and operations, creating new revenue streams, and increasing customer satisfaction and loyalty are all paths to greater success and profit.

The Internet of Things (IoT) is more than the latest buzzword in technology. It’s a real game-changer that can create business value from previously hidden data, especially for manufacturers.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |