Microsoft Business Central vs Dynamics 365: What Enterprises Need to Know Before Choosing

Compare Microsoft Business Central and Dynamics 365 to understand key differences, capabilities, and which solution best fits your enterprise needs.

#DrivingExpertLedTransformation

Compare Microsoft Business Central and Dynamics 365 to understand key differences, capabilities, and which solution best fits your enterprise needs.

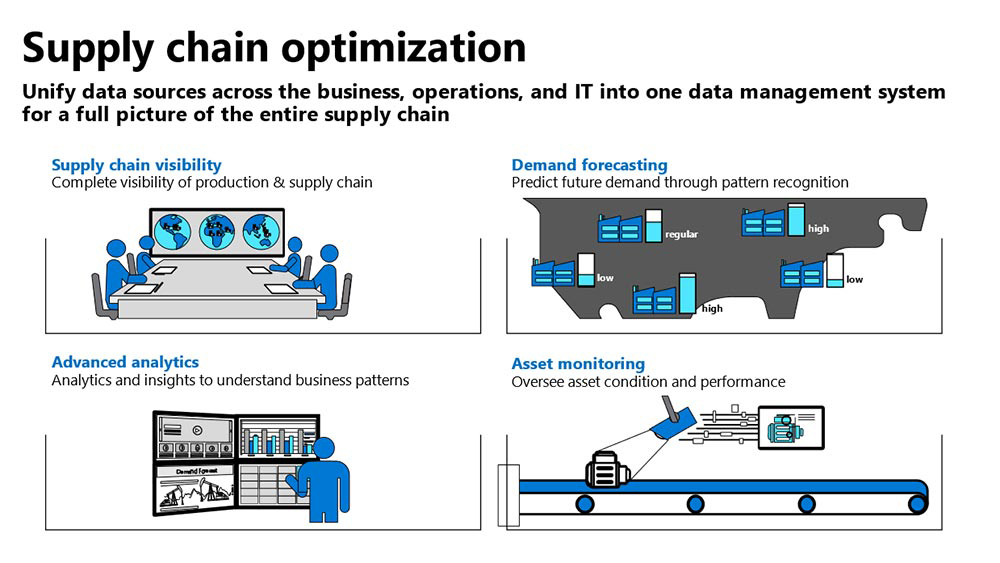

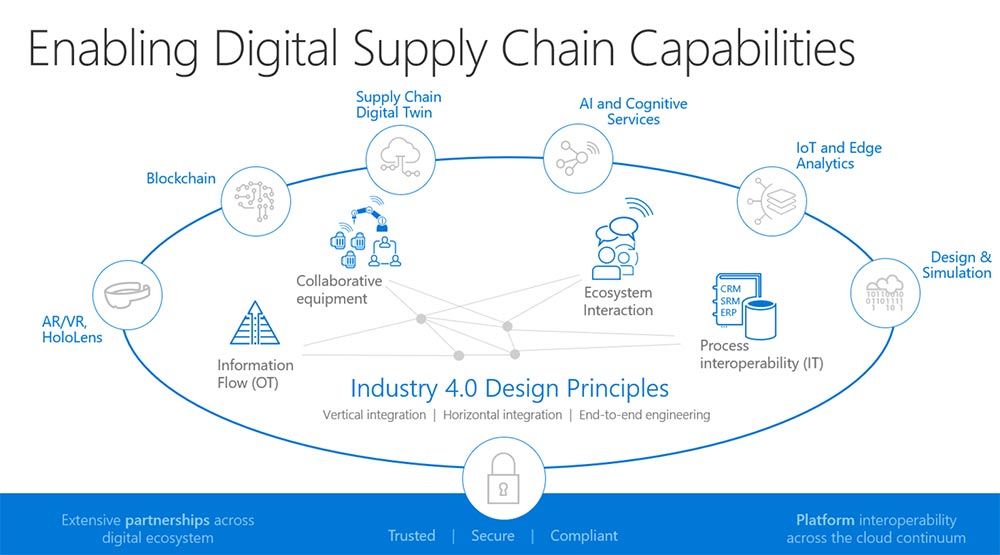

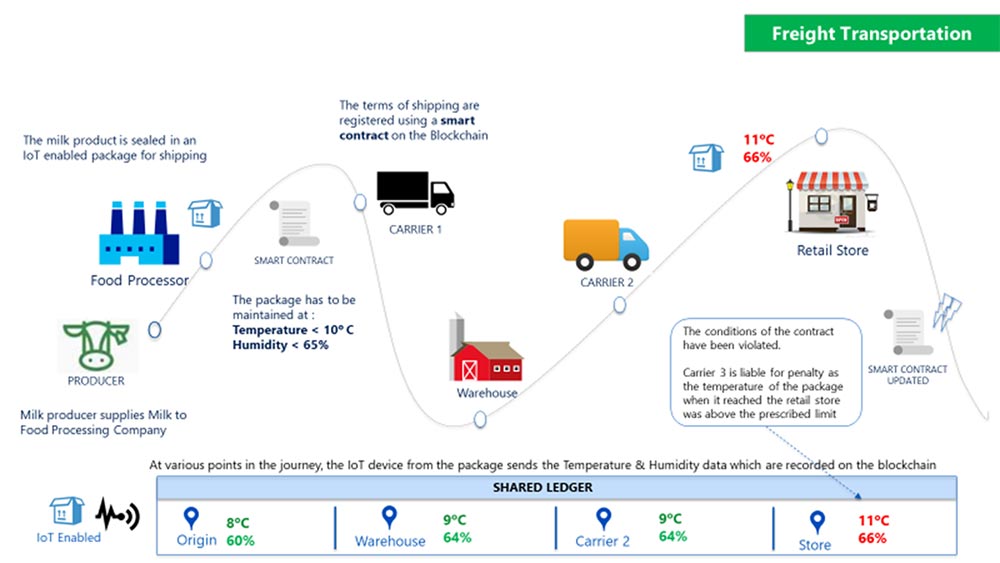

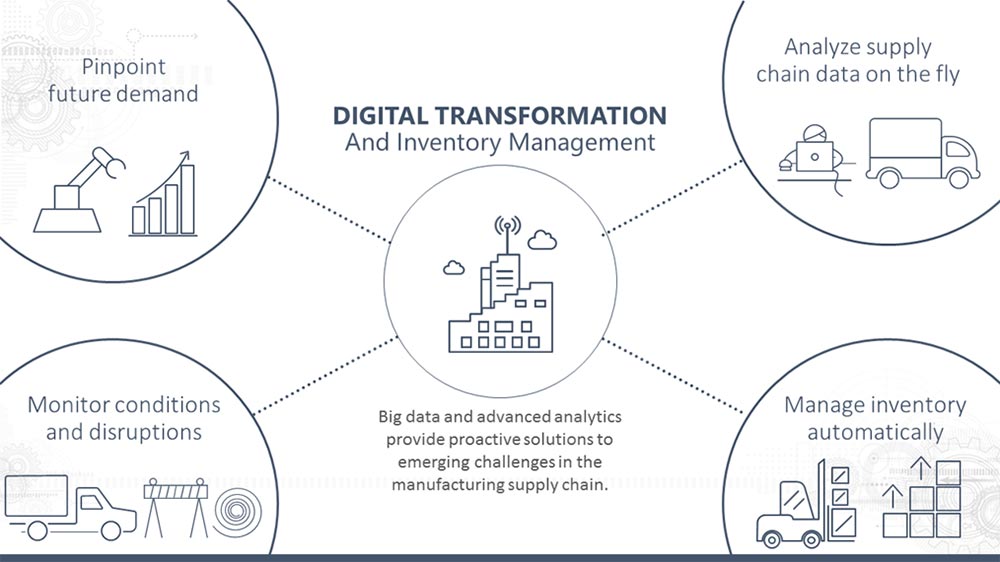

Dynamics 365 Advanced Warehouse Management helps global businesses to boost supply chain resilience with the all-new cloud and edge scale add-ins, allowing them to efficiently distribute their manufacturing and warehousing workloads across geographies.

The COVID-19 pandemic has significantly accelerated the need for remote monitoring and diagnostics of operations and assets.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |